If you have been following the tech world as closely as I have, you know that the term “AI” is being slapped onto everything lately—from toasters to toothbrushes. It can be exhausting. But every once in a while, a piece of news drops that actually makes me sit up and say, “Okay, now that is a game-changer.”

The recent announcement from Samsung and NVIDIA is exactly that kind of news.

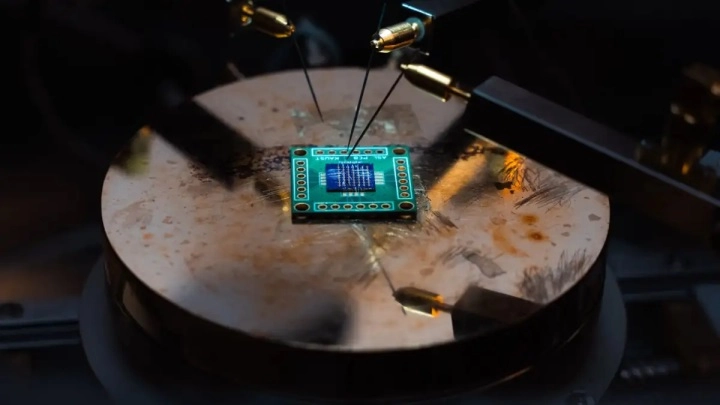

We aren’t talking about a chatbot on your phone. We are talking about the industrial backbone of the world getting a massive nervous system upgrade. Samsung and NVIDIA are teaming up to build a “AI Factory,” and the specs are frankly terrifying (in a good way). They are deploying 50,000 NVIDIA GPUs to create a manufacturing facility that thinks, predicts, and optimizes itself.

Here is my deep dive into why this matters, not just for chips, but for the future of how we make everything.

Not Just a Factory: A Giant Computer That Makes Things

Let’s be honest: when we think of factories, we usually picture sparks flying, conveyor belts moving, and maybe some robotic arms welding car parts. That is the old world.

What Samsung is building with NVIDIA is less like a traditional factory and more like a massive supercomputer that happens to have a physical output.

The Power of 50,000 GPUs

The headline number here is the 50,000 GPUs. To put that into perspective, most cutting-edge supercomputers used for climate modeling or nuclear simulations run on clusters of this magnitude.

Why does a factory need that kind of firepower?

- Real-time Processing: Every sensor, every robot, and every silicon wafer produces terabytes of data.

- Physics Simulations: To predict how materials will behave at the nanometer scale, you need to calculate physics in real-time.

- Training AI Models: The factory learns from its own mistakes.

I find this fascinating because it signals a shift from “automated” (robots following a script) to “autonomous” (robots making decisions based on data).

Enter the “Digital Twin”: The Omniverse Connection

This is the part that excites me the most as a tech enthusiast. The core software powering this beast is NVIDIA’s Omniverse.

If you are not familiar with the concept of a Digital Twin, think of it as the ultimate video game simulation. Samsung is building a virtual replica of their physical factory—down to the millimeter.

Why “Fake” Factories Save Real Money

In the past, if Samsung wanted to change a production line to make a new type of chip, they had to shut things down, retool the machines, and hope it worked. If it failed, they lost millions of dollars in downtime.

With the Omniverse Digital Twin, I see a totally different workflow:

- Simulate: Engineers test the new layout in the virtual world first.

- Break Things: They push the virtual machines to their limits to see where they fail.

- Deploy: Once the simulation is perfect, the software updates the physical robots in the real world.

It is essentially “Ctrl+Z” for manufacturing. You can’t undo a mistake in the real world, but you can undo it in the Digital Twin.

My Take: This integration is going to be crucial for Samsung. The semiconductor race against TSMC is brutal. The company that can iterate faster—testing new chip designs in a virtual environment before cutting silicon—is the one that wins the decade.

Beyond Chips: Robots and Predictive Minds

While Samsung is famous for its semiconductors (the brain of your smartphone), this AI Factory concept extends far beyond just printing circuits. The announcement highlighted that this infrastructure will support robotics and mobile device manufacturing as well.

The End of “Unexpected Downtime”

One of the biggest money pits in manufacturing is when a machine breaks unexpectedly. It halts the entire line.

The AI Factory aims to solve this with Predictive Maintenance.

- How it works: instead of fixing a machine after it breaks, the AI analyzes vibrations, heat, and timing data.

- The Prediction: The system might say, “Hey, the bearing on Robot Arm #42 is going to fail in 72 hours.”

- The Fix: Technicians replace the part during a scheduled break, and production never stops.

It sounds simple, but at the scale of Samsung’s production, this efficiency could save billions. It turns the factory into a biological organism that knows when it’s getting sick before the symptoms even show up.

Why This Partnership Makes Sense Now

I have been analyzing the trajectory of both companies, and this feels like the inevitable convergence of hardware and software.

For NVIDIA: They need to prove that their GPUs and Omniverse platform aren’t just for hype or gaming. Showing that they can power the world’s largest electronics manufacturer is the ultimate flex.

For Samsung: They are in a fierce battle for yield rates (the percentage of chips that actually work). Using AI to spot defects on a microscopic level—before the chip is even finished—is their best bet to overtake competitors like TSMC and Intel.

The Human Element

You might be wondering, “Does this mean robots are taking all the jobs?” It’s a valid fear. However, my perspective is slightly different. These systems are so complex that they require a new tier of human oversight. We aren’t just needing operators anymore; we need “factory pilots” who manage these digital twins. The skill set is shifting, not disappearing.

Final Thoughts: The Industrial Metaverse is Here

I often write about the “Metaverse” as a social space, but the Industrial Metaverse is where the real revolution is happening right now.

Samsung and NVIDIA aren’t just building a factory; they are building a blueprint for the future of Earth’s supply chain. When you hold your next smartphone, realize that it wasn’t just assembled; it was simulated, optimized, and birthed by a neural network running on 50,000 GPUs.

That is pretty mind-blowing.

I’d love to know what you think: Do you trust an AI-run factory to produce higher quality devices, or do you think relying this heavily on automation creates a single point of failure? Let’s chat in the comments below!